Quality control: incoming and outgoing tests for the utmost reliability

Product quality is an essential value for Metalservice. For this reason, our in-house laboratory is equipped with state-of-the-art instruments and managed by highly qualified personnel.

Chemical and mechanical tests are carried out both on incoming raw materials, to verify compliance with the required standards, and on outgoing finished products, to ensure the excellence of the processing performed. Every stage is subjected to rigorous checks, following established procedures.

Upon the customer’s request, quality certificates are issued directly by our laboratory.

The Metalservice in-house laboratory can conduct:

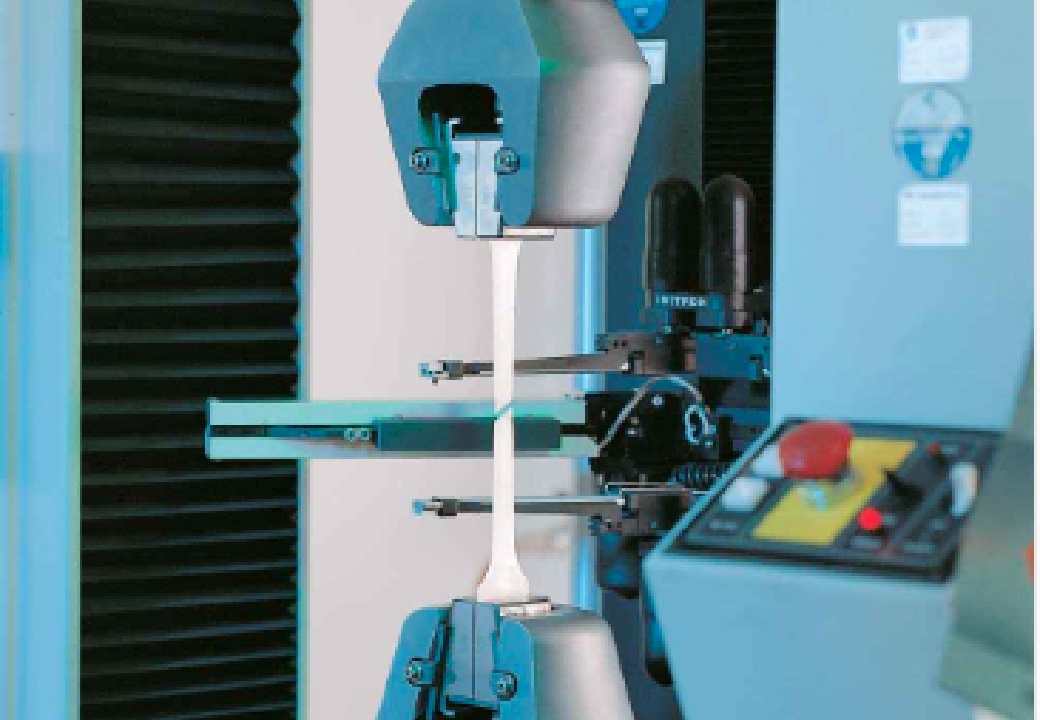

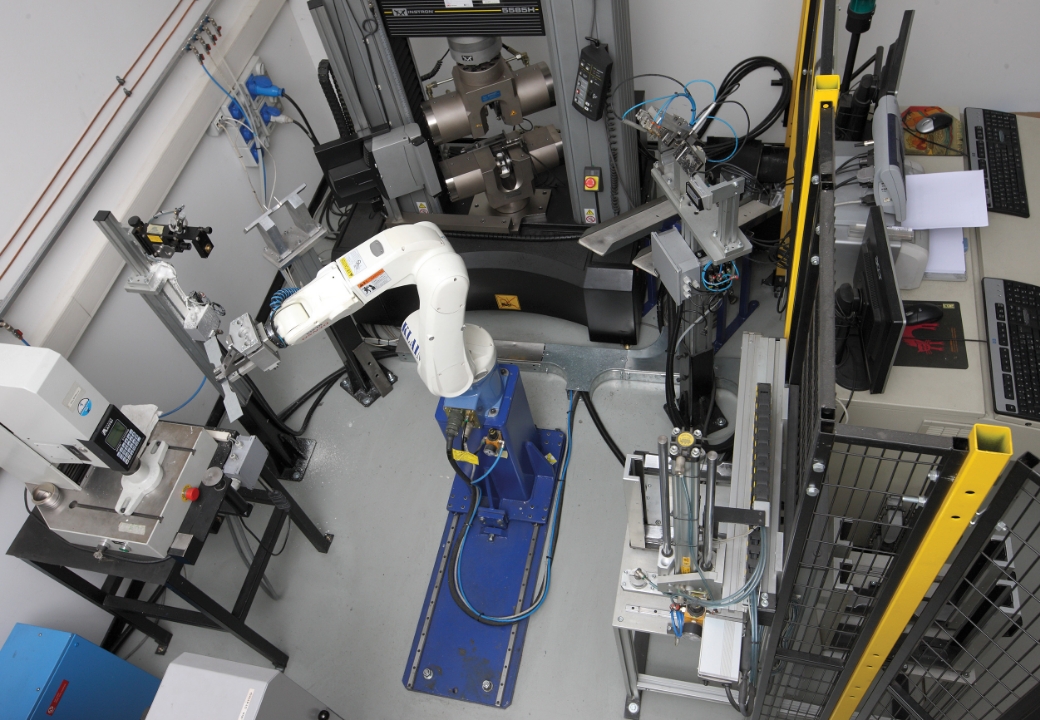

Mechanical analyses

- Tensile analyses in ambient temperature with equipment of 50, 100, 150, 250 (completely robotised) and 300 KN

- Hardness: HRB- HR30T- HB- HV

- Impact test up to a temperature of -60° C with equipment up to 450 joules of power

Chemical analyses

By spark optical emission spectrometry (using quantometers with nitrogen).

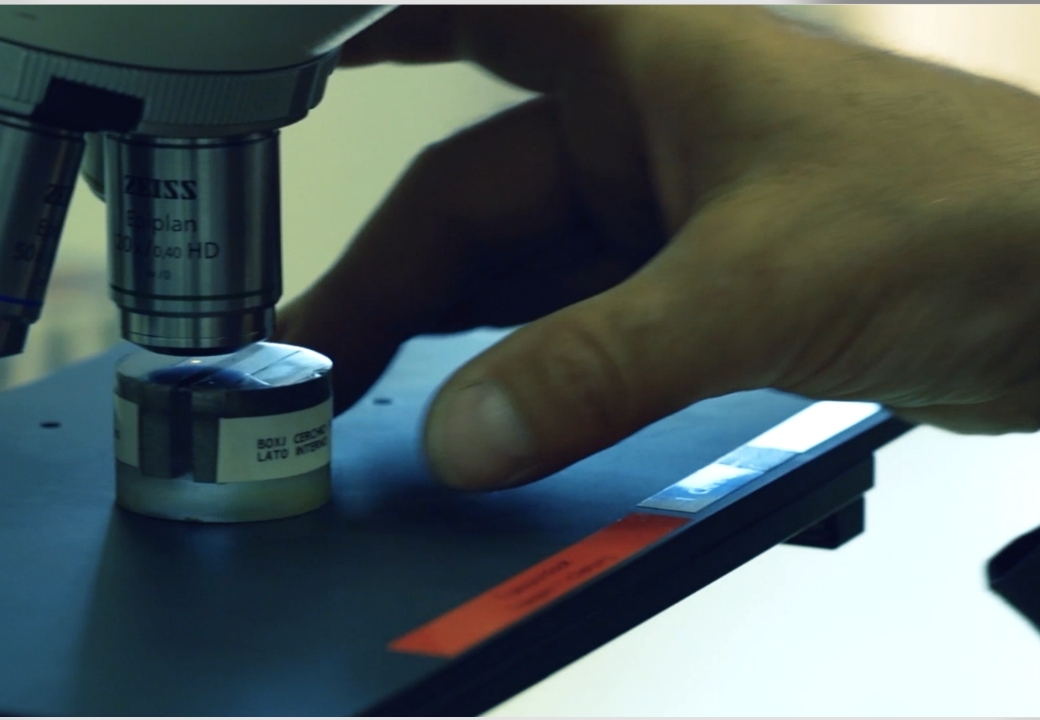

Metallographic analyses

- Grain size analyses

- Inclusions analyses

- Metallurgical defects analyses

Surface analyses

- Roughness

- Coating thickness measurement

- Coating hardness

- Analyses of the characteristics of paint in the pre-painted material

Corrosion tests

Salt spray test

Research

We offer avantgarde services by providing in-depth analyses beyond normal investigation techniques on fractures, metallurgical defects, inclusions, surfaces using a scanning electron microscope (SEM).

Certifications