Metalservice SpA was the first company in the Gabrielli Group to attain, in 1997, ISO 9001 certification, confirming that company processes follow the logic of continuous improvement and of tested and proven productive process.

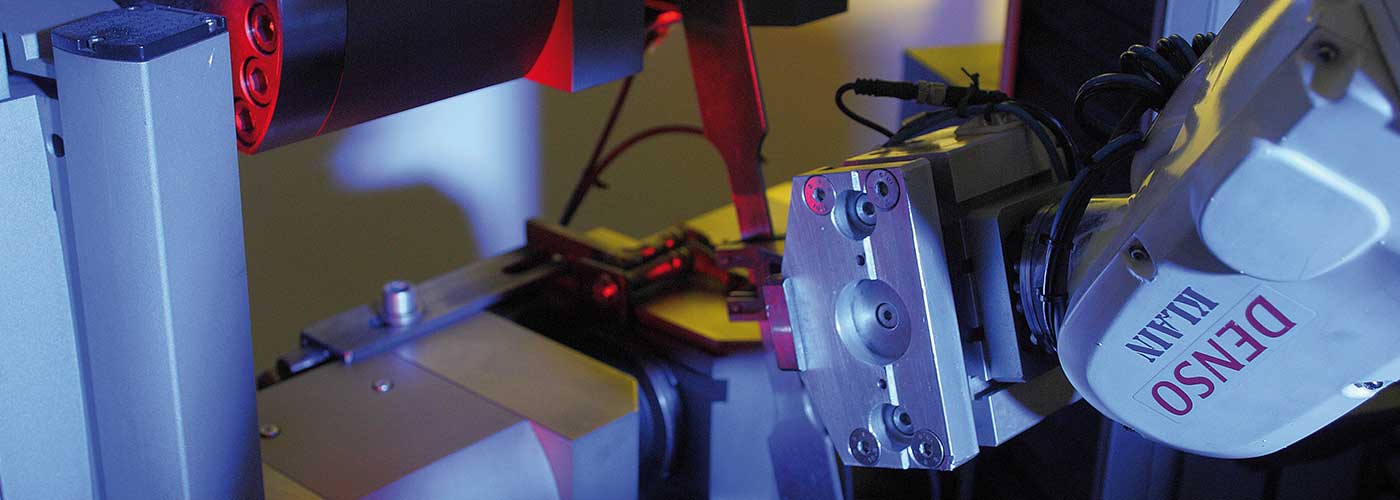

The internal laboratory, outfitted with modern and complete equipment for mechanical and chemical analyses, is staffed by highly qualified personnel and is able to carry out precise tests in each processing phase of the material.

The Cosivi Division of Metalservice can supply cold-rolled structural steel sheets (qualified at their origin by the manufacturer/steel mill) which are ready for subsequent metalwork processing. Supplies comply with the requirements of the 2018 Technical Standards for Constructions, as well as being consistent with the legislative framework defined by the Ministerial Decree of 17 January, 2018 and the favourable opinion of the Central Technical Service of the Supreme Council responsible for overseeing public works.

This is to satisfy that part of the market which is increasingly requiring ready-to-use semi-processed steel.

The Metalservice in-house laboratory can carry out:

Mechanical analyses

- Tensile analyses in ambient temperature with equipment of 50, 100, 150, 250 (completley robotized) and 300 KN

- Hardness: HRB- HR30T- HB- HV

- Impact test up to a temperature of -60° C with equipment up to 450 joules of power

- Bending up to 0T

Chemical analyses

- With spectrometry

Metallographical analyses

- Grain size analyses

- Inclusions analyses

- Metallurgical defects analyses

Surface analyses

- Roughness

- Coating thickness survey

- Coating hardness

- Analyses of the characteristics of paint in the prepainted material

Corrosion tests

- Salt spray test

Research

We offer avantgarde services by providing in-depth analyses beyond normal investigation techniques on fractures, metallurgical defects, inclusions, surfaces using a scanning electron microscope (SEM).